Title: The Unveiled Truth: 7.3l Powdered Metal Rods?

(7.3l powdered metal rods?)

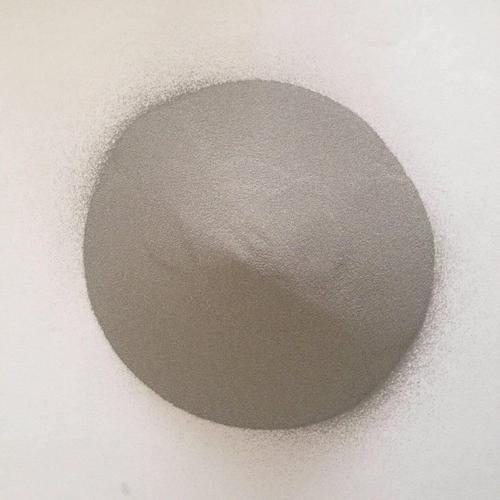

As metal rod technology advances, so does the range of products available to meet different requirements. Among these, powdered metal rods have become increasingly popular due to their versatility and ease of use in various applications. In this article, we’ll explore the concept of powdered metal rods and delve into their potential benefits.

In traditional metal rod production methods, raw materials like iron or steel are typically melted down at high temperatures, shaping them into various sizes. This process is time-consuming, labor-intensive, and requires specialized equipment and processes. To address these limitations, companies began exploring alternative approaches that would streamline the manufacturing process while maintaining high quality standards.

One such approach is using powdered metal rods, which involve melting a mixture of particles into small enough sizes to be cast into a rod. The process begins with selecting a suitable powder, typically consisting of elements like aluminum, copper, zinc, or magnesium, mixed with a carrier metal like iron or steel. The powder is then melted at a controlled temperature and pressure, breaking the individual particles apart and mixing them together to create a consistent composition. The resulting material can then be shaped and extruded into a desired length.

There are several advantages of using powdered metal rods over traditional metal rod production methods:

1. Cost-effectiveness: Powdered metal rods offer lower costs per unit volume compared to traditional metal rods. This is because they require less processing time and energy, leading to fewer defects and inconsistencies in the final product.

2. Versatility: powdered metal rods can be tailored to suit a wide range of applications, from aerospace and automotive components to powertrain systems and medical devices. This flexibility allows for more customization and adaptability in design and functionality.

3. Improved accuracy: Due to the unique properties of powdered metal rods, they can exhibit improved surface finish, reduced corrosion, and increased strength compared to traditional metal rods. This is particularly beneficial in applications where precision and reliability are crucial.

4. Environmental benefits: Powdered metal rods can be produced using environmentally friendly methods, reducing waste and minimizing greenhouse gas emissions associated with traditional metal rod production processes.

Despite its numerous advantages, there are also some concerns surrounding the use of powdered metal rods. One issue is the need for proper heat control during the melting process, as excessive temperatures could lead to warping or cracking of the powder. Additionally, the difficulty in ensuring consistency in particle size and distribution across different batches can affect the overall performance of the rod.

To address these challenges, manufacturers are investing in advanced technologies and techniques, such as computerized powder screening machines and automated shaping equipment. These advancements aim to improve powder mixing, particle size distribution, and thermal management, resulting in better-quality powdered metal rods.

(7.3l powdered metal rods?)

In conclusion, powdered metal rods offer a promising solution to traditional metal rod production methods by offering cost savings, versatility, improved accuracy, and environmental benefits. As research continues to advance in this field, it’s likely that we will see even more innovative and effective ways to utilize powdered metal rods in various industries. Whether you’re looking for a new tool for your next engineering project or just want to stay ahead of the curve in your chosen field, powder metal rods are an excellent choice for those seeking innovative solutions.