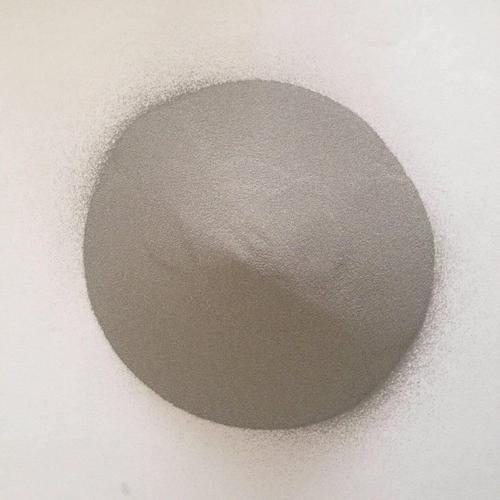

Overview of Round shape Titanium sputtering target vacuum coating material 2N5 purity customized size

Titanium (Ti) is a chemical element with the atomic number 22 and is symbolized as Ti on the periodic table. It belongs to the transition metals group and is known for its low density, high strength-to-weight ratio, and exceptional corrosion resistance. Discovered in 1791 by William Gregor, titanium has become a vital material across numerous industries due to its unique combination of properties.

Feature of Round shape Titanium sputtering target vacuum coating material 2N5 purity customized size

-

Low Density and High Strength: Titanium is about 45% lighter than steel but possesses similar strength, making it ideal for applications where weight reduction is critical without compromising strength.

-

Corrosion Resistance: It forms a passive oxide layer that protects the underlying metal from corrosive substances, including sea water and chlorine, making it highly resistant to corrosion.

-

Biocompatibility: Titanium is well-tolerated by the human body and doesn’t cause adverse reactions, which is why it’s widely used in medical implants and surgical instruments.

-

Heat Resistance: With a melting point of 1,668°C (3,034°F), titanium can withstand high temperatures, making it suitable for aerospace and automotive applications.

-

Non-Magnetic and Non-Toxic: These properties make titanium ideal for applications in MRI machines and other sensitive electronic devices.

-

Fatigue Resistance: Titanium demonstrates excellent resistance to metal fatigue, crucial in cyclic loading applications such as aircraft parts.

.

(Round shape Titanium sputtering target vacuum coating material 2N5 purity customized size)

Parameters of Round shape Titanium sputtering target vacuum coating material 2N5 purity customized size

The precision of the titanium sputtering target vacuum coating material depends on several factors, including the specific titanium oxide particles used, the vacuum pressure and flow rate, the sputtering power, and the thickness of the coated film. In general, the larger the titanium oxide particles and the higher the vacuum pressure, the better the quality of the coating.

The “parameter” you mentioned could refer to the parameters that control these factors. For example:

* Titanium oxide particle size: This parameter determines the number and shape of the titanium oxide particles in the coating film. Smaller particles will have a smoother surface finish and less wear resistance, while larger particles will have a rougher surface finish with more wear resistance.

* Vacuum pressure: The higher the vacuum pressure, the stronger the interaction between the titanium dioxide particles and the substrate, which can lead to better adhesion and retention of the coating. However, increasing the pressure also increases the risk of damage to the substrate or erosion of the coating.

* Sputtering power: The higher the sputtering power, the faster the growth of the titanium oxide particles and the thicker the coating. However, increasing the power also increases the risk of overcorrection and creating a clog in the sputtering system.

The “customized size” parameter refers to the desired coating thickness and size. It is typically measured in microns or millimeters and can be adjusted based on specific requirements such as product application, aesthetic considerations, and performance goals.

Overall, selecting the appropriate titanium sputtering target vacuum coating material and optimizing the parameters for optimal performance requires careful consideration of a variety of factors, including material properties, deposition conditions, and process optimization.

(Round shape Titanium sputtering target vacuum coating material 2N5 purity customized size)

Company Profile

Metal in China is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality copper and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal powder and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQ

(Round shape Titanium sputtering target vacuum coating material 2N5 purity customized size)