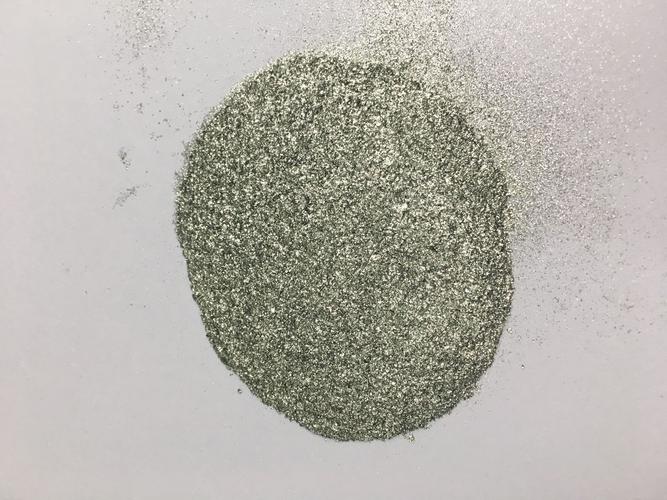

Title: How Big Are Metal Powder?

(How Big Are Metal Powder)

Introduction:

Metal powder is a versatile material that can be used in various applications due to its high strength, resilience, and adaptability. The size and shape of metal powders play a crucial role in determining their performance and functionality.

What is Metal Powder?

Metal powder refers to a mixture of metals, such as steel, aluminum, copper, iron, nickel, and many others. It is made by mixing these metals together in an appropriate proportion, either wet or dry. Metal powder can be either uniform in composition or have varying particle sizes and shapes.

Types of Metal powders:

There are several types of metal powders available, including:

1. Wet powders: These powders are made by mixing metals and water until they reach the desired consistency. They are commonly used for application in construction, manufacturing, and maintenance.

2. Dry powders: These powders are made by mixing metals alone and then forming them into solid form. They are commonly used for manufacturing tools and equipment.

3. Osmogenic metals powders: These powders are made by combining metals and gases. They are commonly used for functional materials, such as adhesives,, and cryptography.

4. Esteroid metals powders: These powders are made by combining metal oxides with esters. They are commonly used for processes such as cleaning and maintenance, production of plastics and synthetic rubber, and various chemical reactions.

5. Liquid metal powders: These powders are made by mixing metal solutions with water. They are commonly used in the processing of metals, including alloying and refining.

Performance and Functionality:

Metal powder has a wide range of properties that make it suitable for a variety of applications. Some of the key features of metal powder include:

1. High strength: Metal powders can provide exceptional strength, making them ideal for applications where fatigue is a concern.

2. High resilience: Metal powders can withstand extreme conditions, such as temperatures and humidity, without breaking down or deforming.

3. Low heat resistance: Metal powders are generally resistant to high temperatures, which makes them useful for applications that require protection from extreme heat.

4. Good thermal conductivity: Metal powders are highly conductive, allowing them to transfer heat quickly and efficiently.

5. Good work hardening: Metal powders can also perform well when applied under high temperatures and pressures, making them suitable for tasks such as woodworking and aerospace engineering.

Conclusion:

(How Big Are Metal Powder)

In conclusion, metal powder has a wide range of properties that make it a valuable tool for a variety of applications. Whether used in construction, manufacturing, or maintenance, metal powder offers unparalleled strength, resilience, and adaptability. As the use of metal powder continues to grow, it will continue to play a critical role in shaping the future of technology.