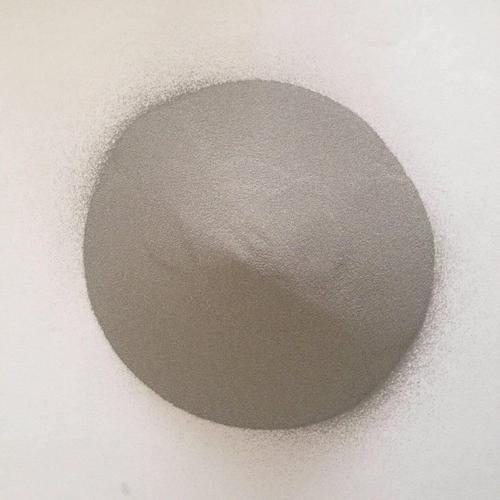

In addition to painting and general maintenance tasks, addingitives can also be used for various purposes such as creating new products, improving equipment performance, and reducing costs. One common additive that is used in many industries is powder metal.

(How To Dry Additive Powder Metal)

However, powders can be expensive to purchase and use, especially when they contain toxic or hazardous substances. Additionally, some additives may not perform as well as intended, and there are concerns about their safety and impact on the environment.

Despite these challenges, using powders in a responsible and safe manner has become increasingly important. This means finding effective ways to prevent or mitigate the effects of the additive while still maintaining the benefits it provides.

In this blog, we will explore some methods for handling and storing powders, as well as discussing the importance of choosing the right type of powder and following proper precautions. We will also provide tips on how to properly identify and label any additives in a product, and what to do if an additive performs poorly or fails to function.

As we continue to develop new technologies and improve our understanding of additive safety and performance, it is essential that we stay informed about new and best practices. By taking these steps, we can ensure that we are protecting our consumers and the environment while preserving the value of our powders.

(How To Dry Additive Powder Metal)

#Additives #Marketing #Product Safety