**Metal Magic: Can Every Metal Get a Powder Coat Makeover?**

(Can Any Metal Be Powder Coated)

Picture this: a world where metals don’t just sit there looking dull. Instead, they flaunt sleek, colorful finishes that resist scratches, rust, and wear. Powder coating makes this possible. But here’s the big question: does *every* type of metal qualify for this glossy upgrade? Let’s dig into the sparkly details.

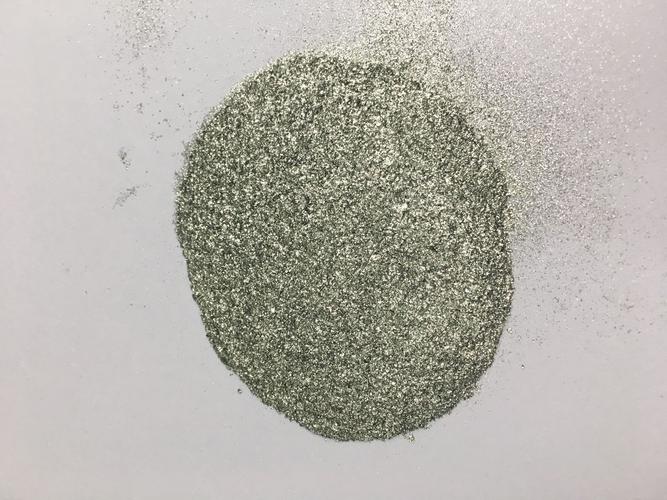

First off, powder coating isn’t some futuristic wizardry. It’s a process where dry powder is sprayed onto a metal surface. The metal gets zapped with an electric charge, making the powder stick like magnets. Then, heat bakes the powder into a smooth, hard shell. The result? A finish tougher than traditional paint. But not all metals play nice with this process.

Take steel. This metal is a powder coating superstar. Steel’s magnetic properties and conductivity make it easy for the powder to cling during the electrostatic phase. Aluminum? Another great candidate. It’s lightweight and conducts electricity well, though it needs a pre-treatment to prevent corrosion. Stainless steel? Yes, but it’s pickier. Without proper sandblasting or chemical prep, the coating might peel off faster than a cheap sticker.

Now, what about metals that don’t conduct electricity? Here’s where things get tricky. Metals like titanium or magnesium alloys might seem exotic, but their natural oxide layers can mess with adhesion. Some can still be coated if engineers tweak the process—maybe using special primers or adjusting temperatures. But others? They’re like that one friend who refuses to dance at a party. They just won’t cooperate.

Copper and brass are interesting cases. They conduct electricity beautifully, but their natural tarnish can create bumps under the coating. Solution? Clean them thoroughly first. Zinc-coated metals (like galvanized steel) also need extra prep. The zinc layer can release gases when heated, causing bubbles in the finish. Pre-baking the metal helps, but it adds steps (and cost).

Then there’s the wildcard: cast iron. It’s porous, so powder coating can fill those tiny gaps and create a smooth shield. But if the cast iron has old grease or rust hiding in its pores, the coating might fail. Blast it clean first, and you’re golden.

What metals are total no-gos? Pure non-conductive materials, like ceramics or certain composites, won’t work. They can’t hold the electric charge needed for the powder to stick. Metals with super-high melting points, like tungsten, are also problematic. The heat required to cure the powder could warp or weaken the metal itself.

Even metals that *can* be coated have limits. Thin sheets of metal might warp under high heat. Delicate parts with intricate details could end up with uneven coverage. That’s why experts often test small samples first.

Real-world applications show how versatile powder coating is. Car parts, bicycles, patio furniture, even kitchen appliances get this treatment. It’s eco-friendly too. Unlike liquid paint, there are no toxic solvents, and overspray can be recycled.

So, can any metal be powder coated? Mostly, but with caveats. Conductivity, surface prep, and heat tolerance decide whether a metal gets that flawless finish. It’s like giving metals a spa day—some need extra exfoliation before the mask sticks. The key is knowing the metal’s quirks and prepping it right.

(Can Any Metal Be Powder Coated)

Next time you see a powder-coated bike frame or a vibrant metal sculpture, remember: science made it shiny, but not every metal gets the VIP treatment without a little work.

Inquiry us

if you want to want to know more, please feel free to contact us. (nanotrun@yahoo.com)