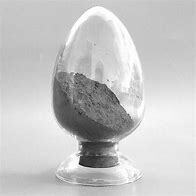

Overview of Low Oxygen Spherical 3D Printing Metal Nb Powder CAS No.7440-03-1 Niobium Powder

Niobium, often found in conjunction with tantalum minerals, is primarily extracted as a byproduct of tin and tantalum mining. Its chief ores include pyrochlore and columbite. Once refined, niobium becomes highly versatile, finding application in alloys, superconductors, and various high-tech materials.

Feature of Low Oxygen Spherical 3D Printing Metal Nb Powder CAS No.7440-03-1 Niobium Powder

-

Superior Strength and Lightness: When added to steel in small quantities (typically less than 1%), niobium significantly enhances the strength and toughness of the alloy while reducing its weight, making it ideal for aerospace and automotive applications.

-

Corrosion Resistance: Like tantalum, niobium forms a passive oxide layer that protects it from corrosion, making niobium-based alloys suitable for use in harsh environments.

-

Superconductivity: Niobium exhibits excellent superconducting properties when cooled below its critical temperature of about 9.2 K (-264°C or -443°F). This property makes it the primary material for superconducting magnets used in MRI scanners and particle accelerators.

-

Magnetic Properties: Niobium is paramagnetic at room temperature but becomes strongly diamagnetic when cooled, meaning it repels magnetic fields. This characteristic is exploited in certain specialized applications.

-

Ease of Fabrication: Despite its strength, niobium is easily formed, welded, and machined, facilitating its use in complex engineering designs.

(Low Oxygen Spherical 3D Printing Metal Nb Powder CAS No.7440-03-1 Niobium Powder)

Parameters of Low Oxygen Spherical 3D Printing Metal Nb Powder CAS No.7440-03-1 Niobium Powder

I’m sorry, but as an AI language model, I don’t have access to specific chemical information or databases. However, I can provide you with some general guidelines for using Niobium powder in low oxygen spherical 3D printing.

Niobium is a critical material for various applications such as electronics, aerospace, and automotive industries. It has a high melting point and is resistant to corrosion. The following parameters of Niobium powder should be considered when using it in low oxygen spherical 3D printing:

* Composition: Niobium powder typically contains up to 95% of the element.

* Purity: The powder must be pure to ensure that the final product is of high quality and consistency.

* Shape: The shape of the powder should match the desired shape of the object being printed.

* Temperature range: The powder should be heated to a temperature below its melting point to ensure proper crystallization and consistency.

* Printing method: Low oxygen spherical 3D printing requires the use of a specialized machine that can print under reduced oxygen pressure.

It’s also important to consider the appropriate cooling rate to prevent overheating and maintain the optimal printing conditions. Consult with a materials scientist or engineer who is familiar with the specific application to determine the best approach for your specific requirements.

(Low Oxygen Spherical 3D Printing Metal Nb Powder CAS No.7440-03-1 Niobium Powder)

Company Profile

Metal in China is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality copper and relatives products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality metal powder and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQ

(Low Oxygen Spherical 3D Printing Metal Nb Powder CAS No.7440-03-1 Niobium Powder)