Title: Sintered Powder Metal forged Or Not?

(Sintered Powder Metal Forged Or Not?)

Introduction:

The world of metalworking is constantly evolving, as technology advances and new materials emerge. One such material that has seen significant growth in popularity is sintered powder metal. This type of metal is often used to create intricate, colorful designs on surfaces such as carvings, sculptures, and even furniture.

What is Sintered Powder Metal?

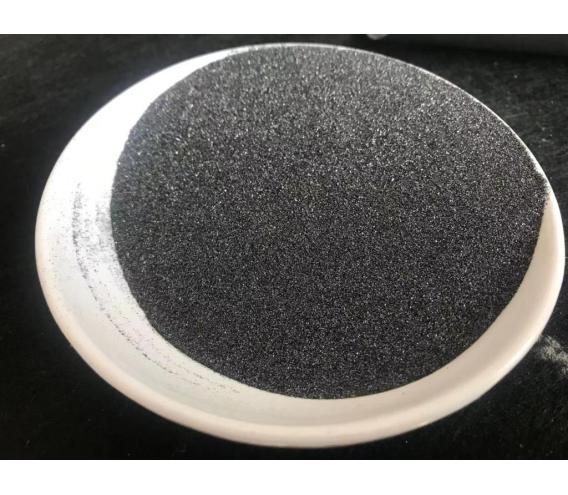

Sintered powder metal refers to metal working using high temperatures and pressures, resulting in a shiny surface without any friction or damage to the metal. The process involves and pressure mixing the powder with the metal to create a hard, durable surface.

Benefits:

One of the main benefits of sintered powder metal is its high strength and durability. It can withstand extreme conditions, such as extreme heat, cold, and pressure, without degradation or failure. Additionally, sintering powder metal can be etched into surfaces with precision, making it an excellent choice for creating intricate, personalized designs.

However, there are also some disadvantages to sintering powder metal. One issue is that the cost of producing sintered powder metal can be high compared to other metals. This is because the process requires specialized equipment and equipment, which can be expensive to purchase and maintain.

Moreover, sintering powder metal may not have the same aesthetic appeal as traditional metals, especially when combined with other materials such as glass or plastic. Additionally, sintering powder metal may be more difficult to shape and work with than traditional metals, particularly if the surface needs to be smooth and uniform.

Conclusion:

(Sintered Powder Metal Forged Or Not?)

In conclusion, sintered powder metal is a promising material for metalworking due to its high strength, durability, and aesthetic appeal. However, like all metals, sintered powder metal has its own challenges, including high costs, difficulty shaping and working with, and the need for specialized equipment. As technology continues to advance, it is likely that sintered powder metal will become an increasingly popular choice for metalworking, providing designers with a unique way to create beautiful, intricate designs.