Title: The Precious Metal: Decoding the Costs of Tungsten: A Visionary Exploration into the Cost-Efficient Resource

(The Precious Metal: Decoding the Cost of Tungsten)

In an era where resources are scarce and precious metals play a crucial role in shaping economies worldwide, understanding the costs of tungsten is essential for determining its value and potentially making it more affordable for industries such as electronics, automotive, and aerospace.

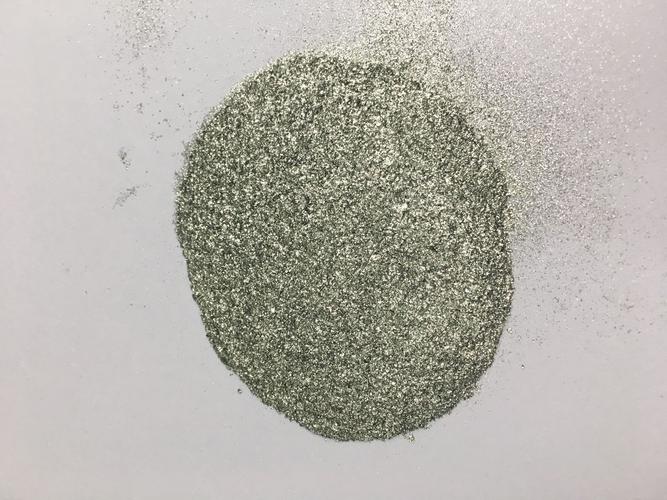

Tungsten is a metal that has been used for centuries to make various applications due to its unique properties and low cost. However, the actual cost of producing tungsten varies depending on several factors such as production capacity, refining conditions, and market demand. Despite this, tungsten remains one of the most expensive metals due to its high material cost and the need for specialized equipment to extract it.

Furthermore, tungsten is also vulnerable to rare-earth elements like gold and iridium, which can lead to fluctuations in its price due to changes in the underlying materials’ prices. This can significantly impact tungsten’s overall value.

Despite these challenges, tungsten holds significant potential for economic development and innovation. For instance, the development of new tungsten-based electronic devices, sensors, and other industrial applications could revolutionize the world economy. Additionally, tungsten is being explored as a substitute for some traditional metals, such as copper, in certain applications due to its low energy consumption and environmental sustainability.

To truly understand the cost of tungsten, we must take a step back and analyze its cost structure. We can start by looking at its primary raw materials. As a mineral, tungsten is made up of the element oxide, which consists of iron oxide dust particles suspended in carbon dioxide gas. The price of mining this ore is determined by factors such as exploration costs, transportation costs, and processing costs.

Additionally, we should consider the transportation and distribution of tungsten. As a semi-precious metal, tungsten requires special handling and storage facilities to ensure its safe and efficient transport across borders. Furthermore, the tungsten industry faces challenges in exporting its product due to the availability of alternative metals in other parts of the world.

Finally, we need to evaluate the demand for tungsten in different regions. For example, tungsten is currently primarily produced in China and Europe, while South America and Asia are becoming increasingly important in the production of tungsten. Understanding the demand patterns in different regions can help us develop effective marketing strategies and strategies to increase the price of tungsten products.

(The Precious Metal: Decoding the Cost of Tungsten)

In conclusion, the cost of producing tungsten is complex and requires careful analysis of its cost structure, transportation and distribution, and demand patterns. By understanding these factors, we can gain valuable insights into the cost of tungsten and develop innovative solutions to increase its value and accessibility for businesses and consumers alike.