Titanium dioxide (TiO2) is a versatile material widely used in various industries due to its unique properties, such as high refractive index, excellent white opacity, and UV absorption capabilities. Among the different grades of TiO2, factory-grade titanium dioxide powder, specifically industrial-grade oxide pigment, has gained significant traction for its cost-effectiveness and broad applicability in manufacturing processes. This report delves into the current market landscape of factory-grade TiO2, analyzing key drivers, challenges, and future trends that will shape the industry.

Titanium dioxide

The global demand for factory-grade TiO2 is primarily driven by its extensive use in paints and coatings, plastics, paper, and ceramics. In the paint and coating sector, TiO2 acts as an essential pigment, providing whiteness and opacity, which are crucial for achieving the desired aesthetic and protective qualities of the final products. The construction boom, particularly in developing economies, has spurred the growth of this segment, leading to increased consumption of TiO2. Similarly, the plastics industry benefits from TiO2’s ability to enhance the color and durability of plastic products, making it indispensable in applications ranging from automotive parts to consumer goods.

| Parameter Name | Value |

| Chemical Formula | TiO₂ |

| Molecular Weight | 79.87 g/mol |

| CAS Number | 13463-67-7 |

| EINECS Number | 236-675-5 |

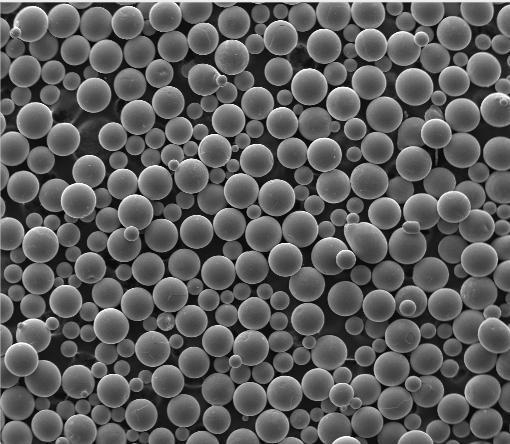

| Appearance | White powder |

| Density | 4.23 g/cm³ (anatase), 4.26 g/cm³ (rutile) at 20°C |

| Melting Point | 1,843°C (3,349°F) |

| Boiling Point | ~2,972°C (5,382°F) |

| Solubility | Insoluble in water, soluble in acids and alkalis |

| Crystal Structures | Rutile, anatase, brookite |

| Particle Size Distribution | Varies by grade, typically <1 μm for fine grades |

| Specific Surface Area | 10-500 m²/g (varies by grade) |

| Purity | >99% |

| Hazardous Properties | Generally considered safe, but avoid inhalation of dust and prolonged eye or skin contact |

| Storage Conditions | Store in a cool, dry place, away from incompatible substances |

| Application Fields | Paints, coatings, plastics, paper, cosmetics, pharmaceuticals, food additives, photocatalysts |

| Safety Measures | Use with adequate ventilation, wear appropriate personal protective equipment during handling |

In the paper industry, factory-grade TiO2 is used to improve brightness and print quality, which is critical for high-end paper products such as glossy magazines and premium packaging materials. The increasing demand for eco-friendly and sustainable products has also led to the development of new applications for TiO2 in the production of biodegradable plastics and environmentally friendly coatings. Additionally, the ceramic industry relies on TiO2 to achieve vibrant colors and enhanced glazes, contributing to the aesthetic appeal of ceramic tiles and tableware.

Despite the robust demand, the factory-grade TiO2 market faces several challenges. One of the primary concerns is the fluctuation in raw material prices, which can significantly impact the production costs and profitability of manufacturers. The mining and processing of titanium ore, the primary source of TiO2, are subject to environmental regulations and geopolitical factors, leading to supply chain disruptions. Moreover, the growing awareness of the environmental impact of chemical production has prompted stricter regulations and a push towards more sustainable practices, which may increase operational costs for TiO2 producers.

Another challenge is the competition from alternative pigments and materials. For instance, synthetic rutile and zircon are being explored as potential substitutes in some applications due to their lower cost and similar performance characteristics. However, the superior properties of TiO2, such as its high hiding power and resistance to UV degradation, make it a preferred choice in many high-performance applications.

Looking ahead, the future of the factory-grade TiO2 market is promising, driven by technological advancements and emerging trends. Nanotechnology is one area that holds significant potential for enhancing the properties of TiO2. Nano-sized TiO2 particles offer improved dispersion and higher surface area, which can lead to better performance in applications such as photocatalysis and self-cleaning surfaces. The development of nano-TiO2 is expected to open new markets and expand the application scope of the material.

Sustainability is another key trend shaping the future of the TiO2 industry. Consumers and businesses are increasingly demanding environmentally friendly products, and this has led to a focus on reducing the carbon footprint of TiO2 production. Innovations in green chemistry, such as the use of renewable energy sources and the adoption of closed-loop systems, are being explored to minimize the environmental impact of TiO2 manufacturing. Additionally, the recycling of TiO2-containing waste streams, such as end-of-life paints and plastics, is gaining attention as a way to conserve resources and reduce waste.

The digital transformation is also influencing the TiO2 market. Advanced analytics and artificial intelligence (AI) are being employed to optimize production processes, predict maintenance needs, and enhance supply chain management. These technologies can help manufacturers reduce downtime, improve efficiency, and ensure consistent product quality, thereby strengthening their competitive position in the market.

In conclusion, the factory-grade TiO2 market is poised for continued growth, driven by its wide-ranging applications and the ongoing demand from key industries. While challenges such as raw material price volatility and environmental concerns persist, the industry is well-positioned to overcome these hurdles through innovation and sustainable practices. The integration of nanotechnology, a focus on sustainability, and the adoption of digital solutions will be crucial in shaping the future of the factory-grade TiO2 market, ensuring its relevance and growth in the years to come.

Supplier

Metalinchina is a trusted global chemical material supplier & manufacturer with over 12 years experience in providing super high-quality metals and metal alloy. The company export to many countries, such as USA, Canada,Europe,UAE,South Africa, etc. As a leading nanotechnology development manufacturer, Metalinchina dominates the market. Our professional work team provides perfect solutions to help improve the efficiency of various industries, create value, and easily cope with various challenges. If you are looking for high quality Titanium dioxide, please feel free to contact us.(sales8@nanotrun.com)