The process of checking cracks in metal using powder involves several steps. The first step is to identify the type and severity of the crack. This can be done by observing the damage caused by the crack, such as discoloration or corrosion.

(what is the process to check cracks in metal with powder)

Once you have identified the type and severity of the crack, the next step is to collect a sample of the metal that needs to be inspected. This sample should be clean and free from debris or contaminants that could affect the analysis.

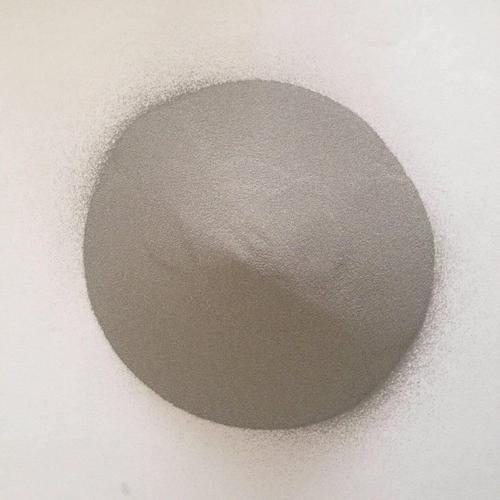

Next, the powder used for inspection must be selected based on the type of metal being checked. For example, if you are inspecting aluminum, you may want to use a powder that contains iron oxide or an iron-based compound. If you are inspecting steel, you may want to use a powder that contains carbon fibers or another material that provides additional strength to the metal.

Once you have selected the appropriate powder, it is time to apply it to the sample of metal. This should be done using a fine mist sprayer or other means of dusting the metal with the powder. The powder should be applied in a pattern that follows the depth and size of the crack, taking care not to oversaturate the metal or cause contamination.

After applying the powder, the metal should be allowed to dry thoroughly. This can take several hours or days depending on the thickness and severity of the crack. Once the metal is dry, the powder should be removed using a soft brush or another means of removing fine particles from the surface.

Finally, the remaining powder residue can be analyzed to determine its composition and strength. This can be done using a variety of techniques, including optical microscopy, X-ray diffraction (XRD), and mechanical testing.

(what is the process to check cracks in metal with powder)

In conclusion, the process of checking cracks in metal using powder involves identifying the type and severity of the crack, collecting a sample of the metal, selecting an appropriate powder, applying the powder to the sample, allowing the metal to dry, removing the powder residue, and analyzing it to determine its composition and strength. This process can provide valuable information about the condition and health of the metal, and can help identify potential problems before they become more serious.