In powder metallurgy, materials that cannot be melted and remelted into small particles or powders are called non-metallurgical materials. These materials may include plastics, resins, resins, and other compounds that do not melt at temperatures above their boiling point.

(what metals can not be used in powder metallurgy)

Plastics, for example, cannot be melted and remelted into powder due to their low melting points. Resins and resins-based compounds can also be difficult to process and recover from powder form due to their complex chemical structures and sensitivity to heat and moisture.

Another important consideration is the size of the particle. Materials that are too small may cause them to break apart during the manufacturing process, leading to defects and quality issues. On the other hand, materials that are too large may require more processing steps to obtain a consistent particle size, which can increase costs and reduce productivity.

Non-metallurgical materials can also have different physical properties than their metal counterparts, such as decreased strength, density, and corrosion resistance. For these reasons, manufacturers typically prefer to use metals for certain applications where these properties are critical.

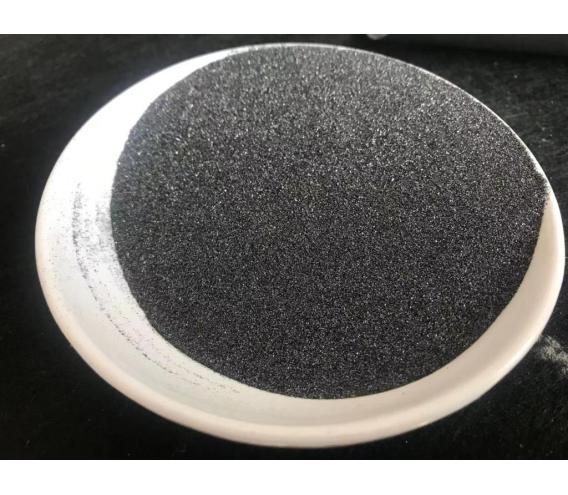

Despite these challenges, there are some metals that can still be used in powder metallurgy. These materials may include aluminum, titanium, steel, and stainless steel, among others. Aluminum has excellent mechanical properties and is commonly used in aerospace, automotive, and medical applications.Titanium is lightweight and durable, making it ideal for high-performance equipment such as aerospace engines and biomedical implants. Steel is strong and can withstand high stresses, making it a popular choice for structural applications. Stainless steel is corrosion-resistant and has a high tolerance for wear and tear, making it ideal for use in harsh environments.

(what metals can not be used in powder metallurgy)

In summary, while non-metallurgical materials cannot be melted and remelted into powder form, there are still some metals that can be used in powder metallurgy. These materials may have different physical properties than their metal counterparts, but they can still provide useful performance characteristics when used in specific applications. As powder metallurgy continues to evolve, we can expect to see even more innovative uses for this versatile material class.