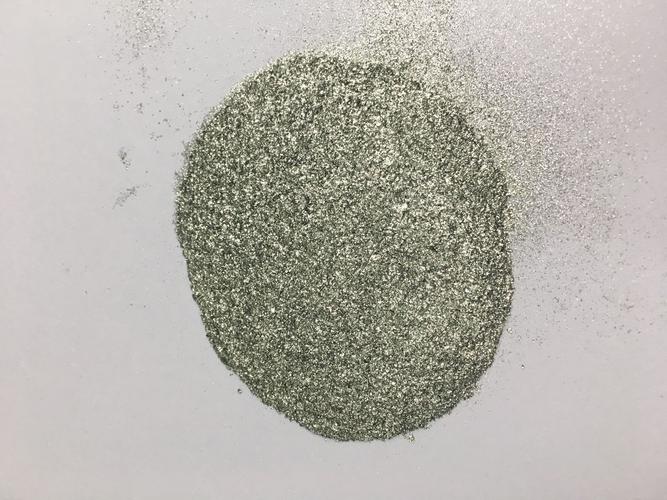

In the field of ceramics, powder-based processing has become a popular method for achieving high-quality results and lower costs compared to traditional methods such as melt processes or sand casting.

(why is powder-based processing more common for ceramic materials than for metals?)

One reason for this is that powder-based processing allows for the creation of smaller, more uniform particles, which can result in improved homogeneity and strength in the final product. This is because powder powders contain more impurities and less binder material, allowing for better separation and distribution of materials throughout the process.

Another advantage of powder-based processing is that it can be used to produce a wide range of shapes and sizes, making it well-suited for specific applications where other methods may not be feasible or cost-effective. Additionally, powder-based processing can also reduce the amount of waste generated during the manufacturing process, making it an environmentally friendly option.

However, there are some limitations to powder-based processing that must be considered. One major challenge is that the quality of the resulting powder can vary depending on the type and purity of the materials being processed. In addition, the size and shape of the resulting particles can also affect their properties, particularly when it comes to their thermal stability and mechanical strength.

(why is powder-based processing more common for ceramic materials than for metals?)

Despite these challenges, powder-based processing continues to be a popular method in the industry due to its many benefits, including improved product quality, reduced costs, and environmental friendliness. As technology advances, it is likely that we will see even more innovative ways to use powder-based processing in the future, leading to even greater improvements in the production of ceramics and other materials.